Ultrananaotech, ULTRANANOTECH

Graphene Film-“Strong and flexible”

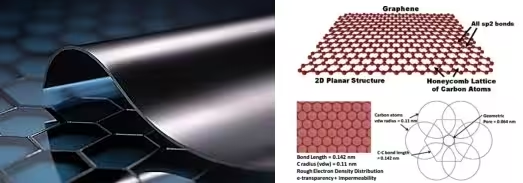

Graphene film is a thin layer of graphene, a highly conductive and flexible material made from carbon atoms arranged in a hexagonal lattice structure in one dimensional plane. Here, are some key properties, applications and synthesis mechanism of graphene film:

Fig: Representation of graphene film

Synthesis mechanism:

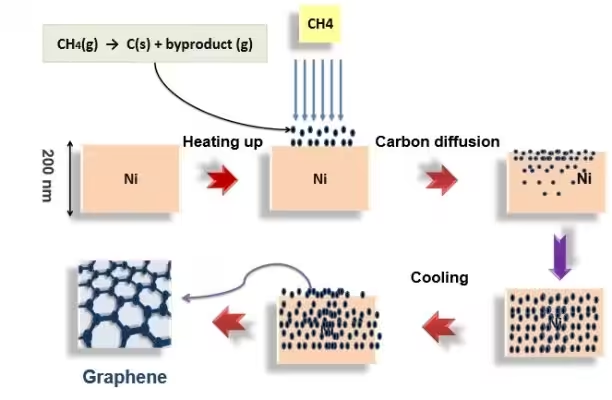

- Chemical Vapor Deposition (CVD): A widely used method for producing large-area graphene powder as well monolayer to multilayer graphene films depending the substrate where graphene film is grown. The quality of graphene film is determined by the number of pinhole defects presence on the film, good coverage graphene films are considered superior over graphene films contain pin holes on its surface. It involves depositing carbon atoms onto a substrate using a precursor gas of hydrocarbons.

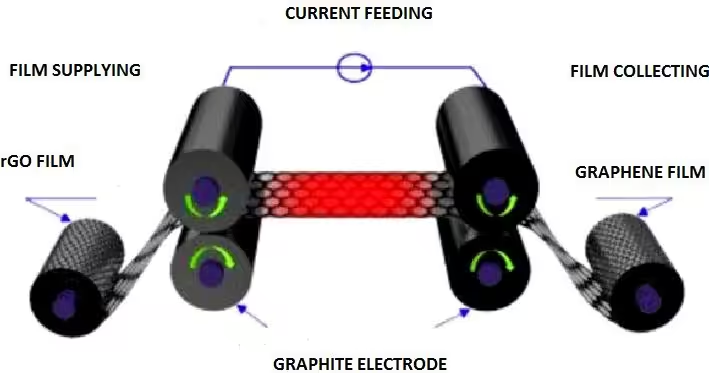

Fig: Schematic representation of preparation of graphene film/powder

- Molecular Beam Epitaxy (MBE): A technique that uses a focused beam of molecules to deposit carbon atoms onto a substrate, allowing for precise control over film thickness and quality.

- Sol-Gel Method: A solution-based approach that involves dissolving graphene oxide in a solvent, followed by deposition onto a substrate and reduction to form graphene. This method generally leads to non-uniform for graphene film

- Langmuir-Blodgett (LB) Method: This method is used to grow or deposit graphene film in solution from graphene powder. A technique that uses a Langmuir-Blodgett trough to deposit graphene layers onto a substrate.

- Mechanical Exfoliation: A method that involves peeling individual graphene layers from graphite using mechanical force. However, the quality of graphene produce by mechanical exfoliation is poor compared to graphene produced by CVD method

- Unzipping Carbon Nanotubes: A method that involves cutting carbon nanotubes to form graphene nanoribbons.

- Electrochemical Exfoliation: A method that uses an electrochemical process to exfoliate graphite and form graphene. The limitation of the method is large scale production.

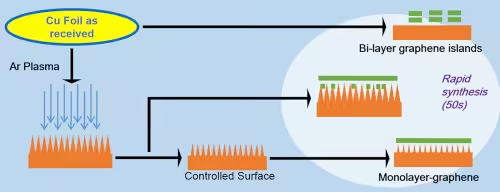

Fig: Synthesis of Monolayer graphene on Cu foil

- Sputtering: A method that involves bombarding a graphite target with ions to deposit carbon atoms onto a substrate.

- Pulsed Laser Deposition (PLD): A method that uses high-energy laser pulses to deposit carbon atoms onto a substrate.

Properties:

- High conductivity: Graphene film is an excellent conductor of electricity and heat.

- Flexibility: Graphene film is highly flexible and can be bent or rolled without breaking.

- Transparency: Monolayer Graphene film is nearly transparent, making it suitable for optoelectronic applications.

- Strength: Graphene film is incredibly strong, with a Young’s modulus of approximately 1 TPa.

- Thinness: Graphene film can be as thin as a single atomic layer (0.3 nm).

Applications:

- Electronics: Graphene film can be used to create flexible displays, wearable electronics, and high-speed electronic devices.

- Energy storage: Graphene film can be used to improve the performance of batteries and supercapacitors.

- Optoelectronics: Graphene film can be used to create ultra-fast photodetectors, optical modulators, and lasers.

Fig: Formation of graphene film

- Biomedical: Graphene film can be used for biosensing, tissue engineering, and drug delivery.

- Coatings: Graphene film can be used as a protective coating for surfaces, providing corrosion resistance and wear protection.

Challenges:

- Scalability: Large-scale production of high-quality graphene film is still a challenge.

- Cost: Graphene film is currently more expensive than traditional materials.

- Integration: Integrating graphene film with other materials and devices can be challenging.

Current research:

- Improving scalability and cost-effectiveness of graphene film production.

- Developing new methods for integrating graphene film with other materials.

- Exploring new applications for graphene film in fields like energy, biomedicine, and aerospace.

Courtesy of: Dr. Shubhadeep Maity, Technical Sales Manager at ULTRANANOTECH PVT LTD