Ultrananaotech, ULTRANANOTECH

Making Stronger, Lighter Composites with Carbon Nanotubes

The quest for materials that are both incredibly strong and remarkably lightweight has led scientists and engineers to one of nature’s most extraordinary structures: carbon nanotubes (CNTs). These microscopic cylindrical marvels are revolutionizing how we create composite materials, offering unprecedented combinations of strength, lightness, and versatility that are transforming industries from aerospace to automotive manufacturing.

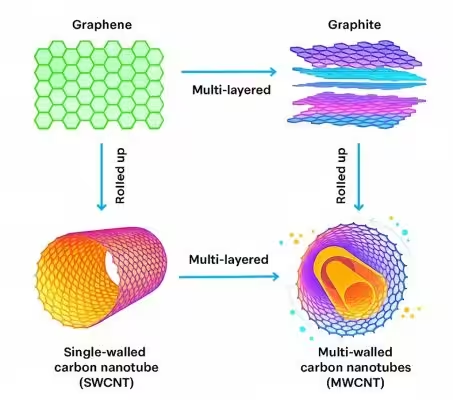

Fig: Structural relationship between graphene, graphite, single-walled and multi-walled carbon nanotubes visualized through schematic diagrams and 3D models.

Carbon nanotubes represent a breakthrough in materials science, essentially consisting of rolled-up sheets of graphene arranged in perfect cylindrical structures. These tubes, measuring just 1-3 nanometers in diameter but potentially several micrometers to centimeters in length, possess exceptional mechanical and thermal conductivity properties. Tensile strengths of CNT reaching up to 100 GPa and specific strengths of 48,000 kN·m/kg, and is consider stronger than steel

Understanding Carbon Nanotubes: Nature’s Engineering Marvel

Structure and Types

Carbon nanotubes exist in two primary forms: single-walled carbon nanotubes (SWCNTs) and multi-walled carbon nanotubes (MWCNTs). Single-walled nanotubes consist of a single layer of carbon atoms arranged in a hexagonal lattice and rolled into a seamless cylinder. Multi-walled nanotubes contain multiple concentric cylinders, with each layer separated by van der Waals forces.

The structural perfection of these materials is remarkable. Unlike conventional materials that fail at only a fraction of their theoretical strength due to defects, carbon nanotubes achieve properties very close to their theoretical limits[6].

Exceptional Properties

The extraordinary properties of carbon nanotubes arise from their unique structure and bonding. Their strength results from the covalent sp² bonds formed between carbon atoms, creating a network stronger than any other known materials. The delocalized electrons in the structure provide excellent electrical conductivity, while the rigid carbon bonds enable superior thermal conductivity.

The most important application of CNT is the composite applications, carbon nanotubes possess an exceptional strength-to-weight ratio. With densities of only 1.3-1.4 g/cm³, they are significantly lighter than metals while being dramatically stronger. Combination of these two properties like light weight and exceptional mechanical properties makes them ideal reinforcement materials for creating composites that are both stronger and lighter than traditional alternatives.

How Carbon Nanotubes Strengthen Composites

Reinforcement Materials

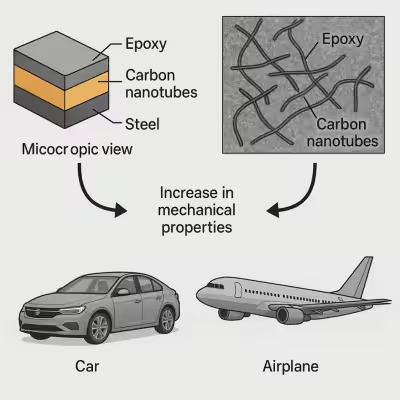

Fig: Schematic and microscopic views of CNT-steel reinforced composites showing layers of epoxy, and the effect of carbon nanotubes on mechanical properties.

The high aspect ratio of CNT enables the formation of an interconnected network, allowing stress to be distributed more evenly than in conventional reinforcements. CNTs also can bridge micro-cracks, preventing them from growing into larger fractures and delaying catastrophic failure. When cracks meet nanotubes, the tubes either bridge the crack or pull out from the matrix, both absorbing significant energies. This energy dissipation helps arrest crack growth and improves fracture resistance. Their nanoscale size allows intimate interaction with the matrix, enhancing both strength and toughness. The combined effects of load transfer, crack bridging, and energy absorption make CNT composites lighter, stronger, and more damage-tolerant. These CNT based light weight composite find wide application in aerospace, automotive, and structural engineering. Overall, CNTs transform composites into materials with superior mechanical performance.

Manufacturing Integration

Fig: Laboratory technician operating CVD equipment for carbon nanotube production

Creating effective CNT-reinforced composites requires careful attention to dispersion and interfacial bonding. Poor dispersion of carbon nanotubes can lead to agglomeration, reducing their effectiveness and potentially creating weak points in the composite. Various techniques have been developed to achieve uniform dispersion, including chemical functionalization, ultrasonic processing, and specialized mixing methods.

Chemical functionalization involves modifying the surface of carbon nanotubes to improve their compatibility with the matrix material. Such modifications improve both dispersion and interfacial strength, leading to better load transfer and overall composite performance.

Manufacturing Carbon Nanotubes: From Laboratory to Industry

Production Methods

CNT-reinforced composites depend on producing high-quality nanotubes production. CNT are broadly prepared by chemical vapor deposition (CVD), arc discharge, and laser ablation. CVD is the most commercially viable, offering low cost, scalability, and good control over nanotube properties. The CVD method of CNT takes place by decomposing hydrocarbons at 500–1000°C in the presence of metal catalysts such as iron, cobalt, or nickel. In contrast, arc discharge vaporizes graphite electrodes using electric arcs above 1700°C, while laser ablation employs high-power lasers to vaporize graphite targets. Although arc discharge and laser ablation produce high-purity CNTs, they are expensive, difficult to scale, and require extensive purification. As a result, CVD dominates industrial production due to its optimal balance of cost, scalability, and property control.

Purification and Processing

Carbon nanotubes prepared by CVD method contain impurities including amorphous carbon, metal catalyst particles, and other carbonaceous materials. Purification typically involves multiple steps: oxidation to remove amorphous carbon, acid treatment to dissolve metal particles, and various separation techniques to isolate high-quality nanotubes.

The purification process is critical for composite applications, as impurities can compromise the mechanical and electrical properties of the final material.

Real-World Applications: Transforming Industries

Aerospace and Defense

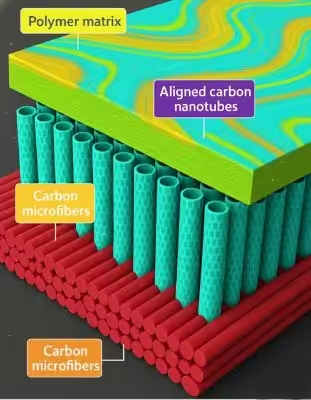

Fig: Structure of a layered composite showing aligned carbon nanotubes at ply interfaces reinforcing carbon microfibers in a polymer matrix.

The aerospace industry has been among the early adopters of carbon nanotube technology, driven by the constant need for materials that are both strong and lightweight. In aircraft construction, every gram of weight reduction can translate to significant fuel savings and improved performance. Carbon nanotubes offer the potential to create composite materials that are 50% lighter than steel and 30% lighter than aluminum while maintaining superior strength.

The unique properties of CNTs make them ideal for thermal management systems in space, where effective heat transfer is critical for equipment operation. Additionally, CNT-reinforced composites show promise for micrometeoroid and orbital debris shielding, providing better protection with less weight penalty. Military applications include body armor and ballistic protection systems. CNT-reinforced composites demonstrate excellent energy absorption capabilities, making them effective at stopping projectiles while remaining lightweight enough for practical use.

Automotive Industry

The automotive sector represents one of the largest potential markets for carbon nanotube composites, driven by regulations demanding improved fuel efficiency by making it Leight the body weight. CNT-reinforced materials are already used in automotive fuel systems, where their electrical conductivity provides antistatic properties to prevent dangerous spark formation. Carbon nanotubes also show promise in automotive energy storage systems. Their lightweight and high-durability properties and inertness allow for the creation of compact, flexible, and more efficient energy storage systems in vehicles.

The Science Behind Superior Performance

Mechanical Enhancement

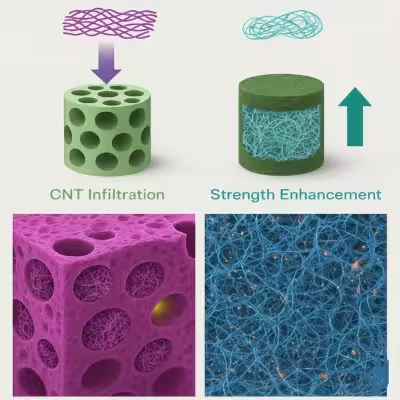

Fig: Visual representation of carbon nanotube reinforced composites showing the infiltration of CNTs into a porous template, bamboo lashing for strength enhancement, and detailed SEM images of the nanotube networks and joints.

The superior performance of CNT-reinforced composites stems from the unique way these materials interact with applied stresses. When a composite containing carbon nanotubes is subjected to load, the stress is initially carried by the matrix material. However, due to the much higher stiffness of the nanotubes, load is quickly transferred to these reinforcing elements through interfacial shear stresses.

Research has shown that even small additions of carbon nanotubes can dramatically improve composite properties. For example, adding just 1% by weight of CNTs to polymer composites can increase tensile strength by 35% and significantly improve toughness and ductility. In cement-based materials, similar additions can improve flexural strength and elastic modulus while enhancing durability.

Challenges and Future Outlook

Production and Cost Considerations

Despite their remarkable properties, several challenges remain in the widespread adoption of carbon nanotube composites. The primary barrier is cost, as high-quality carbon nanotubes remain expensive to produce. Current prices can reach hundreds of dollars per kilogram for research-grade materials, though commercial grades are becoming more affordable.

Quality control and standardization also pose challenges. The properties of carbon nanotubes can vary significantly depending on production conditions, and ensuring consistent quality across large production runs requires sophisticated monitoring and control systems.

Future Developments

The future of carbon nanotube composites looks increasingly promising as production technologies getting mature and costs started declining.

Future Research needs to be focus on new applications and improved processing techniques. Emerging areas of particular interest include CNT-reinforced materials, development of CNT-based sensors and actuators, and integration of CNTs into next-generation energy storage and conversion systems.

Advanced manufacturing techniques such as direct spinning of CNT fibers and precise placement of CNTs within composite structures promise to unlock even greater performance benefits.

Conclusion

Carbon nanotubes represent a transformative technology for creating stronger, lighter composite materials that are reshaping multiple industries. Their exceptional combination of mechanical strength, lightweight properties, and multifunctional capabilities makes them ideal reinforcements for next-generation materials. While challenges remain in terms of cost and manufacturing scale, ongoing technological advances are steadily addressing these barriers.

From aerospace applications where every gram matter to automotive systems demanding improved efficiency, carbon nanotube composites are enabling innovations that were previously impossible with conventional materials.

The journey from laboratory curiosity to commercial reality demonstrates the power of nanotechnology to solve real-world engineering challenges. Carbon nanotubes are not just making materials stronger and lighter – they are fundamentally changing how we think about the relationship between material properties and practical applications, opening new possibilities for innovation across countless industries.

References

- Nurazzi, N. M., Sabaruddin, F. et.al (2021). Mechanical Performance and Applications of CNTs Reinforced Polymer Composites-A Review. Nanomaterials (Basel, Switzerland), 11(9), 2186. https://doi.org/10.3390/nano11092186

- Saberi, A., Baltatu, M. S., & Vizureanu, P. (2024). The Effectiveness Mechanisms of Carbon Nanotubes (CNTs) as Reinforcements for Magnesium-Based Composites for Biomedical Applications: A Review. Nanomaterials (Basel, Switzerland), 14(9), 756. https://doi.org/10.3390/nano14090756

- Arash, B., Wang, Q. & Varadan, V. (2014) Mechanical properties of carbon nanotube/polymer composites. Sci Rep 4, 6479 .

- (2005, February 10). Carbon nanotube manufacturing on a commercial scale: Ready for mass-markets. AZoNetwork.

- Beckman Coulter. (n.d.). Preparation and purification of carbon nanotubes using an ultracentrifuge and automatic dispensing apparatus, and analysis using an analytical centrifuge system. Beckman Coulter, Inc

- Mahalingam, Ponnusamy & Parasuram, B. & Maiyalagan, T & Sundaram, Shanmugam. (2012). Chemical methods for purification of carbon nanotubes-a review. J. Environ. Nanotechnol.. 1. 53-61.

- Sajjad, U. (2023, July 26). Nanotubes in aerospace: Using CNTs to make satellites stronger. AZoNano.

- Ramachandran, K., Boopalan, V., Bear, J.C. et al. (2022) Multi-walled carbon nanotubes (MWCNTs)-reinforced ceramic nanocomposites for aerospace applications: a review. J Mater Sci 57, 3923–3953

- Reghunadhan, A., Shajkumar, A., Abraham, J., & Nimitha, K. C. (2022). Carbon nanotube composites for aerospace applications. In Carbon nanotubes(1st ed., pp. 22). Apple Academic Press.

- Okpala, Charles & Emeka, Udu & Marcel, Egwuagu. (2025). The optimization of polymer-based nanocomposites for advanced engineering applications. World Journal of Advanced Research and Reviews. 25. 755-763. 10.30574/wjarr.2025.25.1.3820.

- Kis, A., Csányi, G., Salvetat, JP. et al. (2004), Reinforcement of single-walled carbon nanotube bundles by intertube bridging. Nature Mater 3, 153–157

Courtesy

Dipanshu Gawde

Ultrananotech Pvt Ltd