Ultrananaotech, ULTRANANOTECH

Nanosponges: Revolutionizing oil Spill clean-up for a cleaner ocean

Introduction

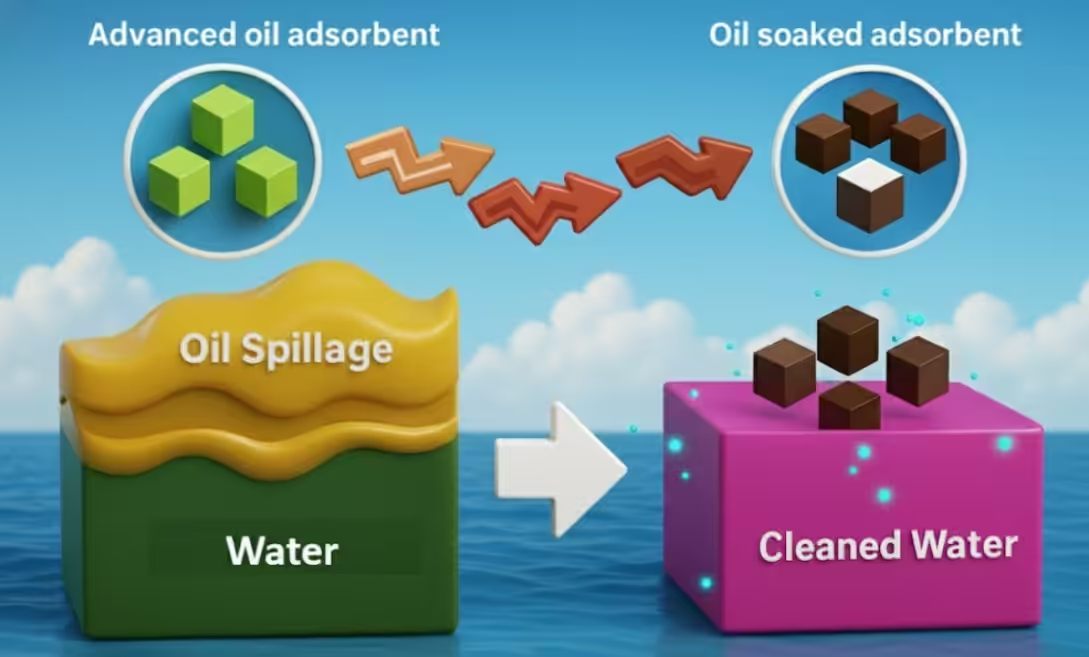

Oil spills represent one of the most devastating environmental disasters our planet faces. From damaging delicate marine ecosystems and threatening wildlife to crippling coastal economies, the impact is profound and long-lasting. For decades, traditional oil spill clean-up methods ranged from physical barriers and skimming vessels to chemical dispersants. These conventional cleaning methods have been served as our primary line of defense against oil spill. Although these methods are significant, they often have limitations. They can be slow, inefficient in harsh conditions, and sometimes cause secondary pollution.

Figure 1: Conventional Method of Oil Spill Cleanup.

What Exactly Are These Nanosponges?

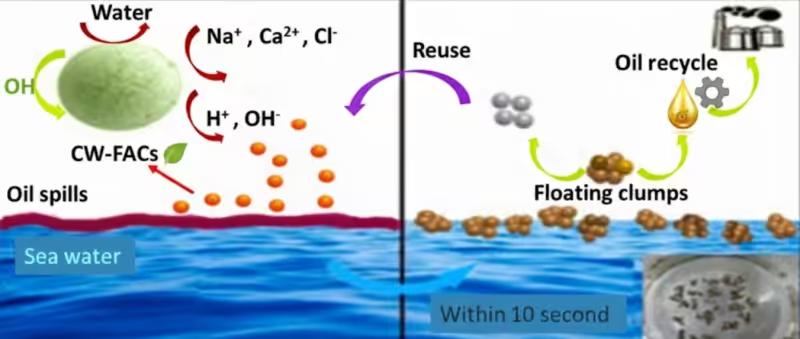

Nanosponges are special materials designed at the nanoscale, smaller than a grain of sand. They have a unique porous, three-dimensional network structure, which enables them to act as a very good adsorbent. They are made from things like carbon nanotubes or eco-friendly polymers, with tiny holes that act like super-absorbent sponges. Unlike regular sponges, nanosponges soak up oil but repel water, which makes them highly effective for oil spill cleanup.

Key Properties of Nanosponges: Their Secret Weapon

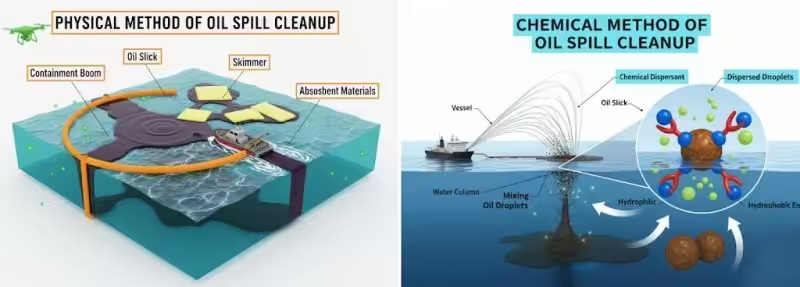

Figure 2: CNT Nanosponge properties.

Nanosponges are packed with unique features that make them superior in oil spill clean-up.

- Super Absorbent: Nanosponges can soak up oil like a super-thirsty sponge, holding up to 100 times their weight. A small piece can clean a big oil mess, making it incredibly efficient.

- Oil-Loving, Water-Hating: They are picky in the best way, grabbing oil while pushing water away. This means they clean spills without harming the ocean or marine life.

- Reusable Magic: Unlike one use clean-up tools, Nanosponges can be squeezed out and used again and again, saving money and reducing waste.

- All Weather Performance: Another advantage of Nanosponges is that it can work in any harsh condition, whether it’s freezing Arctic waters or rough seas, Nanosponges stay strong and keep working, no matter the conditions.

- Eco‑Friendly Solution: Nanosponges reduce the need for chemical dispersants, offering a green alternative that keeps ecosystems safer.

- Lightweight and Easy to Deploy: Nanosponges structure makes them easy to carry, spread, and collect even in large spill areas.

How They Work: The Mechanism of Action

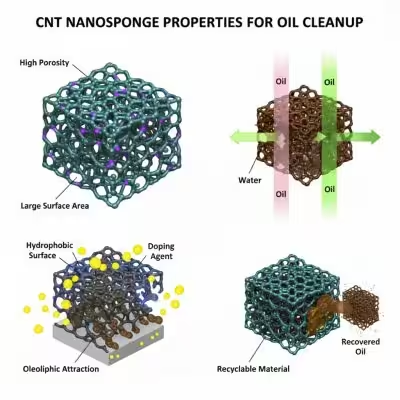

Figure 3: CW-FACs Nano sponge oil spill remediation and recycling process.

Nanosponges interact with oil in several powerful ways:

- Capillary Action: The incredibly small, interconnected pores within the Nanosponge create strong capillary forces. These forces act like tiny straws, actively drawing the oil into the sponge’s internal structure.

- Adsorption: Oil molecules adhere to the vast surface area (extremely high Surface to Volume ratio) of the Nanosponge, effectively binding to it. This binding mechanism of oil to nanosponges can be due to physical attraction or, in some cases, a stronger chemical bond, ensuring the oil is held securely or a combination of both the mechanism.

- Absorption and Retention: Once drawn in, the oil permeates and fills the internal cavities of the Nanosponge, becoming trapped within its matrix. This robust containment prevents the oil from re-entering the water, essentially locking it away.

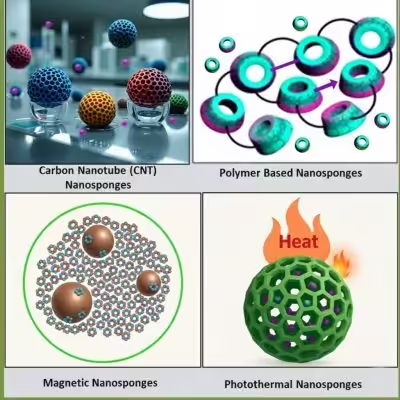

Types of Nanosponges: There are different kinds of Nanosponges, each with unique strengths.

Carbon Nanotube (CNT) Nanosponges: These nanosponges are extremely lightweight but very strong. They have a high level of porosity and a large surface area, which allows them to soak up a huge amount of oil compared to their own weight. They are also chemically stable and can be reused many times without losing their efficiency. Example CNT–graphene composite sponges, CNT aerogel sponges.

CNT based nanosponges are widely used for large‑scale oil spills, such as those that happen in oceans or big industrial areas. They are also a great choice when we need a sponge that can handle tough conditions and won’t easily break down, even in harsh chemical environments.

Polymer‑Based Nanosponges: These are made from biodegradable or recyclable polymers, so they are very eco‑friendly. They are flexible, easy to make, and can even be designed to absorb only specific substances like oil, dyes, or toxins. Example β‑Cyclodextrin polymer nanosponges, cellulose‑based nanosponges.

Polymer‑based nanosponges are extremely useful in removing oil spills when an oil spill happens in places that are environmentally sensitive, like rivers and wetlands. They are perfect when we want a solution that avoids causing secondary pollution. They also work well for small to medium spills where we want something affordable and safe for nature.

Magnetic Nanosponges : These composite nanosponges have magnetic nanoparticles inside them. Magnetic nanosponges, or nanocomposites, offer a promising solution for cleaning up oil spills by effectively adsorbing and removing oil from water using magnetic forces. This means we can guide them or collect them easily using external magnets. They can be quickly separated from water after they absorb oil, which makes the clean‑up process much easier. Example, CNT–graphene-Fe3O4 nano composite sponges, CNT-aerogel-Fe₃O₄ (iron oxide) nano composite sponges., magnetic carbon nanosponges etc.

Magnetic nanosponges come into play in oil spill removal when there is a demand for targeted clean‑up, like in a confined tank or a localized spill. They are also very helpful in situations where we need to retrieve them quickly after absorption or in areas that are hard to reach by hand.

Photothermal Nanosponges: These nanosponges are coated or combined with materials that respond to light as well as heat. They can use in sunlight or infrared light to release the oil they have absorbed from the spill, which means we can reuse them many times with very little effort. Example Polydopamine‑coated CNT sponges, graphene–photothermal hybrid nanosponges.

Photothermal nanosponges due to their unique ability of responding to light or heat, are widely used in removing oil spills in sunny regions or open waters where there’s plenty of sunlight. They are especially helpful when we want to recover oil without using heavy machines, and they’re a great choice for long term projects where reusability saves both time and cost.

Figure 4: Shows different types of Nanosponges.

A Clear Advantage Over Traditional Methods

Nanosponges offer compelling benefits that address many limitations of conventional oil spill responses:

- High Absorption Capacity: Unlike many sorbents that become saturated quickly, Nanosponges can absorb oil many times of their own weight – some research reports indicate over 200 times! This is mainly attributed to the high surface to volume ratio or high aspect ratio. More exposed surfaces can easily absorb more oil.

- Superior Selectivity: By attracting oil and repelling water, Nanosponges achieve a much cleaner separation of pollutants, leaving minimal water residue within the recovered oil. This is a significant improvement over methods that can collect large volumes of water along with the oil.

- Potential for Reusability: A truly game-changing aspect is the ability of many Nano sponges to be regenerated. Once saturated, the absorbed oil can often be squeezed out or recovered through simple processes like heating, allowing the Nano sponge to be reused multiple times. This dramatically reduces waste and operational costs.

- Faster Response and Reduced Secondary Pollution: Their efficiency leads to quicker clean up times, and by precisely targeting oil without introducing new harmful chemicals, they mitigate the risk of secondary environmental damage often associated with dispersants.

- Versatility: With ongoing research, nanosponges are being developed to function effectively in diverse environments, from tropical waters to challenging cold and icy conditions.

Challenges and Future Outlook

Nanosponges show great promise, but challenges remain. Scaling up production is complex and costly. Additionally, the long-term mechanical and chemical stability of some nanosponges needs further research to ensure durability in harsh marine environments. Future research could focus on improving production methods, making them economically viable, enhancing durability in harsh environments, and integrating nanoparticles for better oil degradation. Combining nanosponges with renewable energy sources like solar power is also a promising area. This technology has potential for environmental cleanup, and ongoing research can help unlock its benefits.

In the future, scientists are also working on developing biodegradable nanosponges that naturally break down after use to further reduce environmental impact. Multifunctional nanosponges that can capture heavy metals, microplastics, or toxic chemicals along with oil are another exciting possibility. Smart nanosponges with sensors or color change indicators to show when they are saturated are being explored. Large‑scale manufacturing techniques like 3D printing or roll‑to‑roll fabrication could help in speeding up production and reducing costs. Greater collaboration between industries, researchers, and government support can drive commercialization and real‑world applications. Moreover, long‑term studies on how nanosponges interact with different ecosystems will ensure their safe and sustainable use in the future.

Conclusion: A Brighter Future for Our Oceans

The rise of nanosponges marks a significant step towards a cleaner, healthier marine environment. By offering a fast, efficient, and environmentally responsible solution to oil spills, nanosponges can transform the way we respond to ecological disasters. With continued innovation and collaboration between scientists, industries, and environmentalists, we are moving closer to a future where our oceans can recover faster, thrive longer, and shine brighter.

Reference

- Sehrawat, M., Singh, V., Rani, M., Kalra, C., Bharadwaj, S., Rani, R., Bisht, A., & Pratap Singh, B. (2024, August 15). Nano-welded carbon nanotube sponges for efficient oil spill remediation. Journal of Cleaner Production, 467, 142841. https://doi.org/10.1016/j.jclepro.2024.142841

- Sun, J., Li, R., Wang, X., Zhao, C., Song, Q., Liu, F., Wang, Z., Liu, C., & Zhang, X. (2023, July). Marine oil spill remediation by Candelilla wax modified coal fly ash cenospheres. Chemosphere, 330, 138619. https://doi.org/10.1016/j.chemosphere.2023.138619

- Mishra, S., Chauhan, G., Verma, S., & Singh, U. (2022, May). The emergence of nanotechnology in mitigating petroleum oil spills. Marine Pollution Bulletin, 178, 113609. https://doi.org/10.1016/j.marpolbul.2022.113609

Courtesy :

Abdul Jalil ,

(B.Sc Chemistry -Karimganj College, Assam)

Intern- Ultrananotech Pvt Ltd, Bengaluru