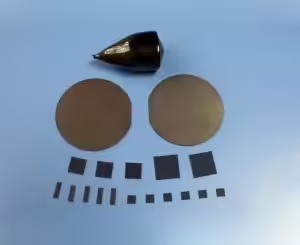

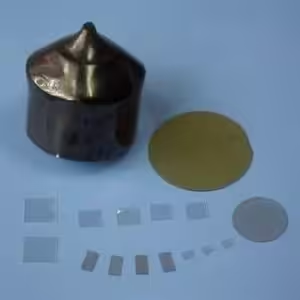

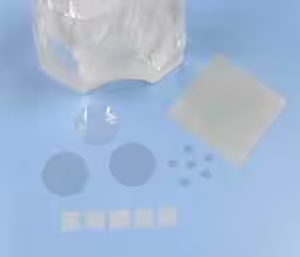

Sputtering target

Call for Price

We are instrumental in offering a broad spectrum of Sputtering Targets. These Sputtering Targets are made up of finest quality material and advance technology. These Sputtering Targets are corrosion resistant which attracts the clients most.

Alloy sputtering target

Oxide sputtering target or ceramic target Metal

Boride sputtering target Metal

carbide sputtering target

Fluoride sputtering target

Nitride sputtering target

Selenide sputtering target

Silicide sputtering target

Call for priceFeatures:

- From standard, single element materials to custom compounds, small circular to Multiple Tile and stepped constructions, and commercial grade to ultra-high purities

- We utilize a variety of specialized processing techniques such as hot pressing, hot isostatic pressing (HIP), and cold isostatic pressing (CIP), induction vacuum melting, and vacuum casting to produce homogenous, fine-grained, high-density materials that conform to the strictest application standards

- Provides a full range of sputtering target materials including precious metals, pure metals, alloys, ceramics, cermet, boride, oxides, carbides, nitrides, silicates, and fluorides Purities range from commercial-grade (99.5%) to ultra-high (99.9999%)

- Backing plates used in the sputtering process are essential to creating a quality thin film deposition for your product. We offer to backplates in both standard configurations and custom dimensions to meet your specific requirements.

- We also offer complete bonding services to provide a complete solution

1. Pure Metal Sputtering Target Al, Sb, Bi, B, CD, C, Ce, Cr, Co, Cu, Dy, Er, Eu, Gd, Ge, Au, C, Hf, Ho, In, Ir, Fe, La, Lu, Mg, Mn, Mo, Nd, Ni, Nb, Pd, Pt, Pr,Re, Ru, Sm, Se, Sc, Ag, SI, Ta, Tb, Tm, Sn, Ti, W, V, Yb, Y, Zr, Zn, La, Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, Lu, Sc,Y

2. Alloy Sputtering Target AlCu, AlCr, AlMg, AlSi, AlSiCu, AlAg, AlV, CaNiCrFe, CaNiCrFeMoMn, CeGd, CeSm, CrSi, CoCr, CoCrMo, CoFe, CoFeB, CoNi, CoNiCr, CoPt, CoNbZr, CoTaZr, CoZr, CrV, CrB, CrSi, CrCu, CuCo, CuGa, CuIn, CuNi, CoNiPt, CuZr, DyFe,DyFeCo, FeB, FeC, FeMn, GdFe, GdFeCo, HfFe, IrMn, IrRe, InSn, MoSi, NiAl, NiCr, NiCrSi, NdDyFeCo, NiFe, NiMn, NiNbTi,NiTi, NiV, SmCo, AgCu, AgSn, TaAl, TbDyFe, TbFe, TbFeCo, TbGdFeCo, TiAl, TiNi, TiCr, WRe, WTi, WCu, ZrAl, ZrCu, ZrFe,ZrNb, ZrNi, ZrTi, ZrY, ZnAl, ZnMg

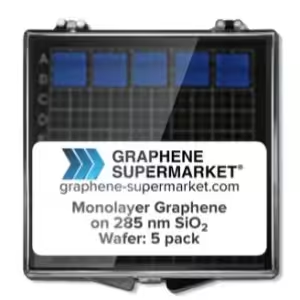

3. Oxide sputtering Target or ceramic target Al2O3, Sb2O3, ATO, BaTiO3, Bi2O3, CeO2, CuO, Cr2O3, Dy2O3, Er2O3, Eu2O3, Gd2O3, Ga2O3, GeO2, HfO2,Ho2O3, In2O3, ITO, Fe2O3, Fe3O4, La2O3, PbTiO3, PbZrO3, LiNbO3, Lu3Fe5O12, Lu2O3, MgO, MoO3, Nd2O3, Pr6O11, Pr,(TiO2) 2, Pr2O3, Sm2O3, Sc2O3, SiO2, SiO, SrTiO3, SrZrO3, Ta2O5, Tb4O7, TeO2, ThO2, Tm2O3, TiO2, TiO, Ti3O5, Ti2O3, SnO2, SnO, WO3, V2O5, YAG, Y3Al5O12, Yb2O3, Y2O3, ZnO, ZnO: Al, ZrO2 (unstabilized) , ZrO2-5-15wt% CaO)

4. Metal boride sputtering Target: Cr2B, CrB, CrB2, Cr5B3, FeB, HfB2, LaB6, Mo2B, Mo2B5, NbB, NbB2, TaB, TaB2, TiB2, W2B, WB, VB, VB2, ZrB2

5. Metal Carbide Sputtering Target: B4C, Cr3C2, HfC, Mo2C, NbC, SiC, TaC, TiC, WC, W2C, VC, ZrC

6. Fluoride sputtering Target AlF3, BaF3, CdF2, CaF2, CeF3, DyF3, ErF3, HfF4, KF, LaF3, PbF2, LiF, PrF3, MgF2, NdF3, ReF3, SmF3, NaF, Cryolite, Na3AlF6, SrF2, ThF4, YF3, YbF3

7. Nitride Sputtering Target AlN, BN, GaN, HfN, NbN, Si3N4, TaN, TiN, VN, ZrN

8. Selenide sputtering Target Bi2Se3, CdSe, In2Se3, PbSe, MoSe2, NbSe2, TaSe2, WSe2, ZnSe

9. Silicide Sputtering Target Cr3Si, CrSi2, CoSi2, HfSi2, MoSi2, NbSi2, TaSi2, Ta5Si3, TiSi2, Ti5Si3, WSi2, V3Si, VSi2, ZrSi2

Related products

High-Temperature Superconducting